In the dynamic world of supply chain management, few phenomena are as disruptive and perplexing as the bullwhip effect. This term vividly captures the erratic fluctuations that can ripple through the supply chain, amplifying small changes in demand into large variances in supply. Understanding the bullwhip effect is crucial for businesses aiming to optimize their supply chain operations, reduce costs, and improve service levels.

What is the Bullwhip Effect?

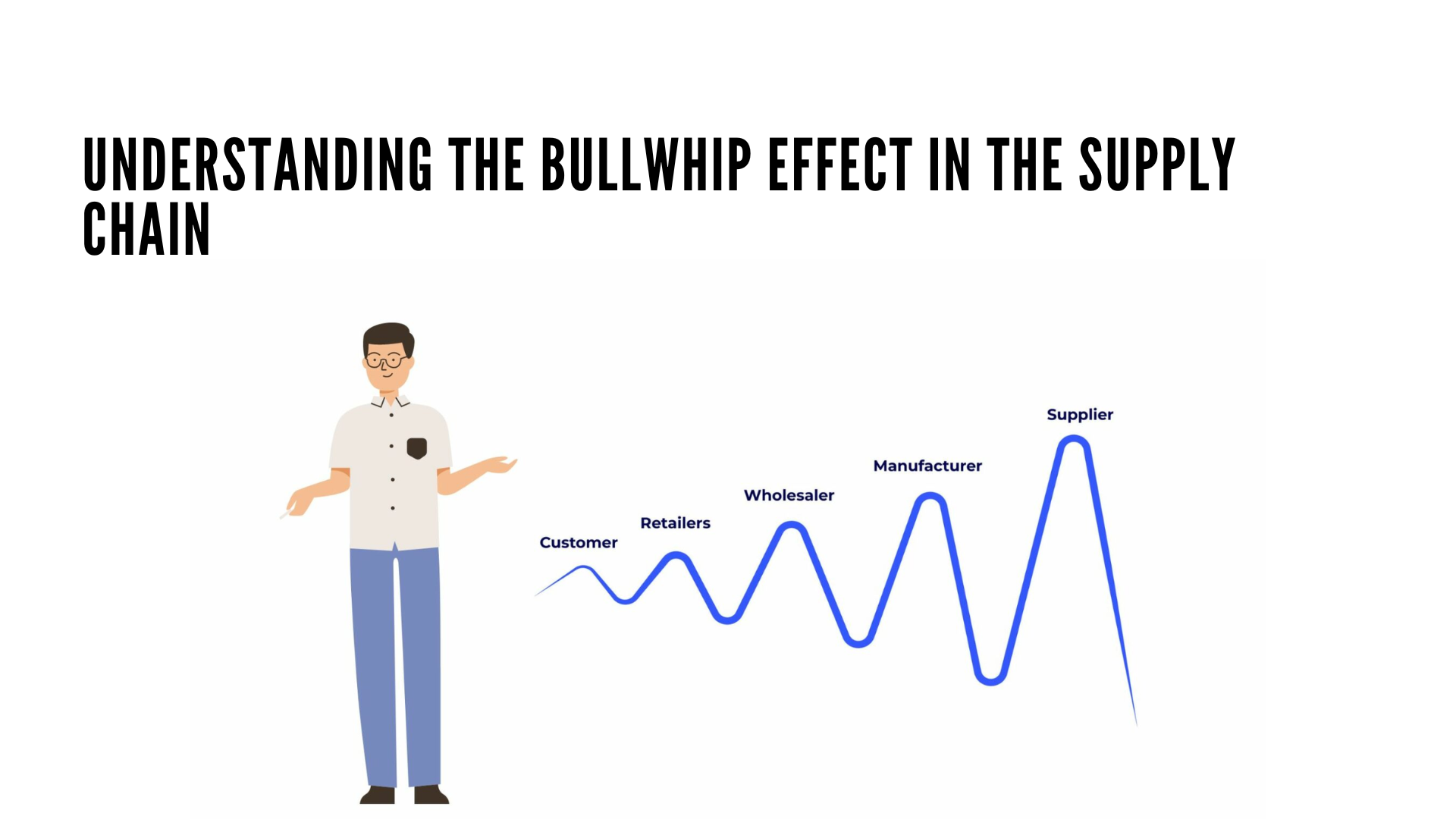

The bullwhip effect describes how small changes in consumer demand can lead to increasingly larger fluctuations in orders and inventory levels as you move up the supply chain—from retailers to wholesalers, manufacturers, and suppliers. Like the cracking of a whip, where a slight flick of the wrist leads to a large and rapid movement at the end of the whip, minor variations in demand can become exaggerated as they travel up the supply chain.

Key Characteristics of the Bullwhip Effect:

- Amplification of Demand Fluctuations: Minor shifts in consumer demand can cause significant changes in orders and inventory.

- Increased Variability: Each level of the supply chain experiences greater variability in orders compared to the actual end-customer demand.

- Inventory Imbalances: Overproduction or stockouts can occur due to the misalignment between supply and demand.

Causes of the Bullwhip Effect

Several factors contribute to the bullwhip effect, each amplifying demand variability in unique ways:

- Demand Forecasting Errors

Companies often rely on forecasts to predict future demand. When these forecasts are based on inaccurate or outdated information, they can lead to significant discrepancies between expected and actual demand. Each link in the supply chain bases its forecast on the orders from the previous link, not on actual consumer demand, which can perpetuate inaccuracies.

Example: A retailer’s forecast for the next month’s demand might be based on the last month’s orders, which were unusually high due to a temporary promotion. This inflated forecast is then passed up the chain, leading to overproduction.

- Order Batching

Businesses often place large orders at infrequent intervals to benefit from economies of scale or to meet minimum order quantities. This practice can cause significant variability in the supply chain, as each order might be significantly larger than the actual demand, leading to stockpiling and sudden spikes in production.

Example: A distributor might place a large order once a quarter to secure bulk discounts, causing manufacturers to ramp up production temporarily, even though actual consumer demand is stable.

- Price Fluctuations

Promotions, discounts, and price changes can lead to spikes in consumer purchasing, which can distort the actual demand pattern. These temporary increases in sales are often interpreted as a permanent shift in demand, causing upstream suppliers to overreact.

Example: A temporary price discount might lead consumers to buy more than they need in the short term. Retailers then order more stock to meet this temporary demand surge, which signals an artificial increase in demand to wholesalers and manufacturers.

- Supply Chain Lag Times

Delays in communication and transportation can cause a mismatch between supply and demand. When there’s a time lag in receiving updated demand information or in shipping products, companies might overreact to perceived shortages or surpluses.

Example: A retailer might experience a delay in receiving products due to transportation issues. To compensate, they place larger orders, fearing future shortages, which then signals an increased demand to suppliers.

- Lack of Coordination and Communication

Ineffective communication and lack of coordination between supply chain partners can exacerbate the bullwhip effect. When each link in the chain operates in isolation, reacting independently to demand changes, the cumulative effect can lead to significant distortions in the supply chain.

Example: If a supplier isn’t informed about a sudden spike in demand due to a promotion at the retail level, they may not increase production in time, leading to stockouts and subsequent overordering.

Consequences of the Bullwhip Effect

The bullwhip effect can have several detrimental impacts on supply chain performance and business operations:

- Excessive Inventory Costs

The amplification of demand fluctuations often leads to overproduction and excess inventory, which tie up capital and increase storage costs.

Impact: Companies may find themselves holding large amounts of unsold stock, which can become obsolete or require heavy discounting to clear.

- Increased Production and Distribution Costs

Frequent adjustments to production schedules and distribution plans can lead to inefficiencies, increased labor costs, and higher transportation expenses.

Impact: Manufacturers may need to adjust production runs frequently, leading to higher operational costs and potential overtime payments.

- Decreased Customer Service Levels

Stockouts and delays in supply can result in missed sales opportunities and lower customer satisfaction. Businesses might struggle to meet consumer demand consistently, leading to lost sales and damaged relationships.

Impact: Retailers may experience empty shelves, frustrating customers and driving them to competitors.

- Strained Supplier Relationships

Erratic ordering patterns can strain relationships with suppliers, who may struggle to meet fluctuating demand or maintain consistent production levels.

Impact: Suppliers may impose penalties for large, unpredictable orders or may be unable to meet sudden spikes in demand.

Mitigating the Bullwhip Effect

To combat the bullwhip effect, companies can implement several strategies aimed at stabilizing demand signals and improving supply chain coordination:

- Improve Demand Forecasting

Adopting more sophisticated forecasting techniques, such as demand sensing and predictive analytics, can help reduce forecast errors and better align production with actual demand.

Strategy: Utilize historical data, real-time market analysis, and advanced algorithms to create more accurate demand forecasts.

- Enhance Communication and Collaboration

Encouraging closer collaboration and communication among supply chain partners can lead to better alignment and more synchronized operations.

Strategy: Implement collaborative planning, forecasting, and replenishment (CPFR) processes to share demand information and coordinate responses.

- Reduce Order Batching

Companies can minimize the impact of order batching by placing smaller, more frequent orders, thus smoothing out demand signals.

Strategy: Use techniques like Just-in-Time (JIT) inventory management or adopt vendor-managed inventory (VMI) systems to reduce order sizes and frequencies.

- Stabilize Prices

Avoiding frequent price changes and promotions can help maintain a more consistent demand pattern, reducing the likelihood of overreaction to temporary demand spikes.

Strategy: Implement everyday low pricing (EDLP) strategies or reduce the frequency and magnitude of promotions.

- Shorten Supply Chain Lead Times

Reducing lead times can help companies respond more quickly to actual demand changes, minimizing the need for large buffer inventories and reducing the impact of delays.

Strategy: Optimize logistics and transportation networks, and invest in faster, more flexible production systems.

Conclusion

The bullwhip effect is a significant challenge in supply chain management, with far-reaching impacts on costs, efficiency, and customer satisfaction. By understanding its causes and implementing strategies to mitigate its effects, businesses can improve their supply chain resilience and performance. As supply chains become more complex and global, managing the bullwhip effect will remain a critical focus for achieving operational excellence and competitive advantage.