In today’s fast-paced business environment, efficient capacity planning is crucial for maintaining operational efficiency and meeting customer demands. Rough Cut Capacity Planning (RCCP) is a method used to balance capacity and demand at an aggregate level, ensuring that production plans are feasible and aligned with business goals. But is RCCP the right approach for your business? Let’s explore its features, benefits, and potential drawbacks to help you make an informed decision.

What is Rough Cut Capacity Planning?

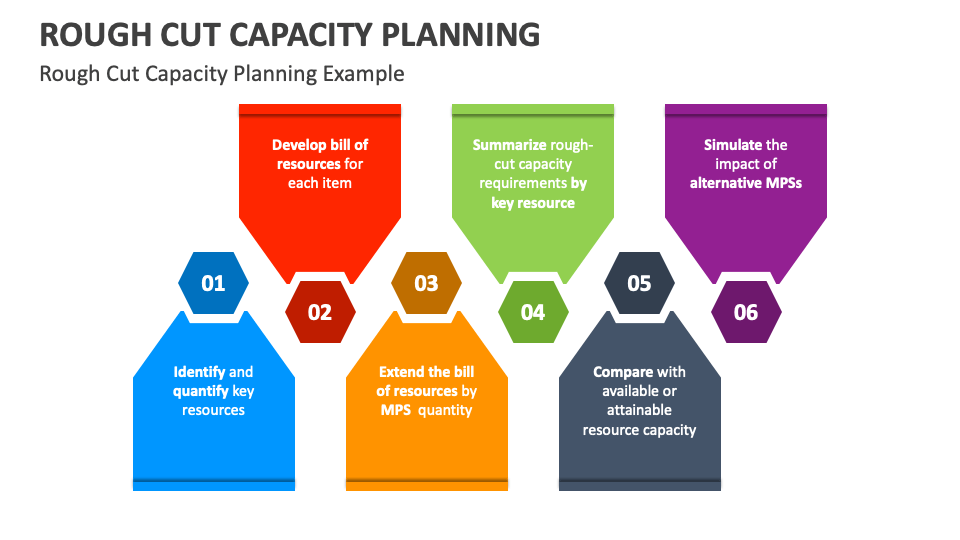

Rough Cut Capacity Planning is a high-level capacity planning process that evaluates the capacity of critical resources—such as labor, machinery, and materials—against the master production schedule (MPS). Unlike detailed capacity planning, RCCP does not dive into the specifics of every single operation but focuses on the broader picture, providing a quick and rough estimate of whether the production plan is achievable with the available resources.

Benefits of RCCP

- Quick and Efficient: RCCP provides a rapid assessment of capacity needs without the complexity of detailed planning. This makes it ideal for initial planning stages or when time is of the essence.

- Resource Allocation: By identifying potential capacity issues early, RCCP helps businesses allocate resources more effectively, preventing bottlenecks and ensuring smoother operations.

- Strategic Decision-Making: RCCP offers a high-level view that supports strategic decision-making. Businesses can use this information to adjust production plans, invest in additional resources, or shift workloads to meet demand.

- Cost-Effective: Since RCCP is less detailed than other planning methods, it requires less time and fewer resources, making it a cost-effective solution for many businesses.

Potential Drawbacks

- Lack of Detail: The primary drawback of RCCP is its lack of granularity. It does not account for specific operational details, which can lead to discrepancies between planned and actual capacity.

- Assumptions and Estimates: RCCP relies heavily on assumptions and rough estimates, which can introduce inaccuracies. If the assumptions are off, the capacity plan may not be reliable.

- Not Suitable for Complex Operations: For businesses with highly complex operations or those requiring precise capacity planning, RCCP might not provide the level of detail needed to ensure accurate planning and execution.

Is RCCP Right for Your Business?

To determine if RCCP is the right fit for your business, consider the following factors:

- Business Size and Complexity: Smaller businesses or those with less complex operations might benefit more from RCCP due to its simplicity and efficiency. Larger businesses with complex operations may require more detailed planning methods.

- Planning Horizon: RCCP is ideal for medium-term planning. If your business requires long-term strategic planning or short-term detailed scheduling, other methods might be more appropriate.

- Resource Constraints: If your business often faces resource constraints and needs to quickly assess capacity feasibility, RCCP can provide valuable insights without the need for detailed analysis.

- Decision-Making Needs: If your primary goal is to support high-level strategic decisions rather than detailed operational planning, RCCP can offer the necessary overview.

Conclusion

Rough Cut Capacity Planning is a valuable tool for businesses seeking a quick and efficient way to assess capacity against demand at a high level. While it has its limitations, RCCP can be highly effective for certain types of businesses and planning scenarios. By carefully evaluating your business’s specific needs and operational complexity, you can determine whether RCCP is the right capacity planning approach for you.

Implementing RCCP can lead to better resource allocation, more strategic decision-making, and improved operational efficiency. However, it’s important to recognize when a more detailed planning method might be required to achieve the desired level of accuracy and control. Ultimately, the right capacity planning approach will depend on your business’s unique requirements and goals.